You're staring at two wheels that look nearly identical, but one costs $200 and the other costs $800. Both are aluminum, both have five spokes, both claim to be "high performance." The salesperson launches into technical jargon about grain structure and manufacturing processes, but you're left wondering if that $600 difference actually matters for your daily driver.

Here's what most people don't realize: the manufacturing process determines everything about a wheel's performance and price. Forged wheels offer superior strength but cost significantly more. Cast wheels provide good performance at a lower price. Flow-formed wheels split the difference.

The problem is knowing when those differences actually matter. This guide explains what each manufacturing process can and can't do so that you can match wheel construction to your actual driving needs and budget.

What Are Forged Wheels?

Forged wheels start life as a solid chunk of aluminum alloy that gets hammered and pressed under extreme pressure until it forms a wheel shape. This isn't gentle molding; we're talking about forces that would crush a car applied in controlled, precise ways.

The Forging Process Reality

The forging process requires massive hydraulic presses and precisely controlled heat application. A solid aluminum billet gets heated to around 900°F, then pressed under thousands of tons of pressure into the rough wheel shape. Multiple forging operations gradually refine the shape until it's close to the final form.

After forging, the wheel gets machined to precise dimensions. This subtractive process removes material to create the final spoke design, bolt pattern, and finish surfaces. The combination of forging and machining results in wheels that are both incredibly strong and precisely manufactured.

Real Performance Benefits

The strength advantage isn't just theoretical. Forged wheels can be made thinner and lighter while maintaining superior impact resistance. For performance driving, this translates to reduced unsprung weight, which improves handling, acceleration, and braking response.

The weight savings are significant; typically 15-30% lighter than cast equivalents. That might not sound like much, but unsprung weight affects vehicle dynamics more than static weight. Every pound saved at the wheels feels like 3-4 pounds removed from the car's body.

Where Forged Wheels Make Sense

Forged wheels justify their premium cost in specific applications: track cars that see repeated high-stress conditions, off-road vehicles encountering serious impacts, and high-performance street cars where every performance advantage matters.

They're also popular for show cars and luxury applications where cost isn't the primary consideration. The machining capabilities of forged construction allow for complex designs that aren't possible with other manufacturing methods. For those looking at larger sizes, 18-inch rims in forged construction offer the most significant weight savings benefits.

What Are Cast Wheels?

Cast wheels get made by pouring molten aluminum into a mold and letting it cool. This sounds simple, but modern casting techniques can produce surprisingly sophisticated wheels with good strength and attractive designs.

Manufacturing Process Details

Gravity casting is the most basic method, relying on gravity to fill the mold with molten aluminum. Low-pressure casting uses modest pressure to force metal into the mold, creating denser castings with fewer air pockets. Counter-pressure casting provides the highest quality cast wheels by using vacuum and pressure to eliminate porosity.

Cast Wheel Advantages

Cost is the obvious advantage; cast wheels cost significantly less to manufacture than forged alternatives. The tooling costs are lower, production rates are higher, and less specialized equipment is required.

Realistic Performance Expectations

Modern cast wheels aren't the weak, heavy options they were decades ago. Advanced casting techniques and alloy formulations have significantly improved their strength and weight characteristics. Quality cast wheels can handle normal driving demands without issues.

Flow-Formed Wheels: The Middle Ground

Flow-formed wheels represent a compromise between cast affordability and forged performance. The process starts with a cast wheel center, then uses specialized machinery to stretch and compress the barrel section under high pressure and temperature.

Understanding the Flow-Forming Process

Flow-forming takes a cast wheel preform and spins it at high speed while rollers apply pressure to stretch the barrel outward. The process work-hardens the aluminum and improves its grain structure, creating strength approaching forged levels in the barrel section.

The wheel center remains cast, which limits overall strength compared to fully forged construction. However, the barrel, where most impact stresses occur, receives the benefit of the flow-forming process.

Performance and Cost Balance

Flow-formed wheels typically cost 30-50% more than cast equivalents but 40-60% less than forged options. They offer genuine performance improvements over cast wheels, including weight reduction and increased impact resistance.

For many performance applications, flow-formed wheels provide the best balance of cost and capability. They're particularly popular for larger wheel sizes, where the weight savings become more significant. Popular finishes, such as black alloy wheels, are available in flow-formed construction, combining aesthetic appeal with enhanced performance characteristics.

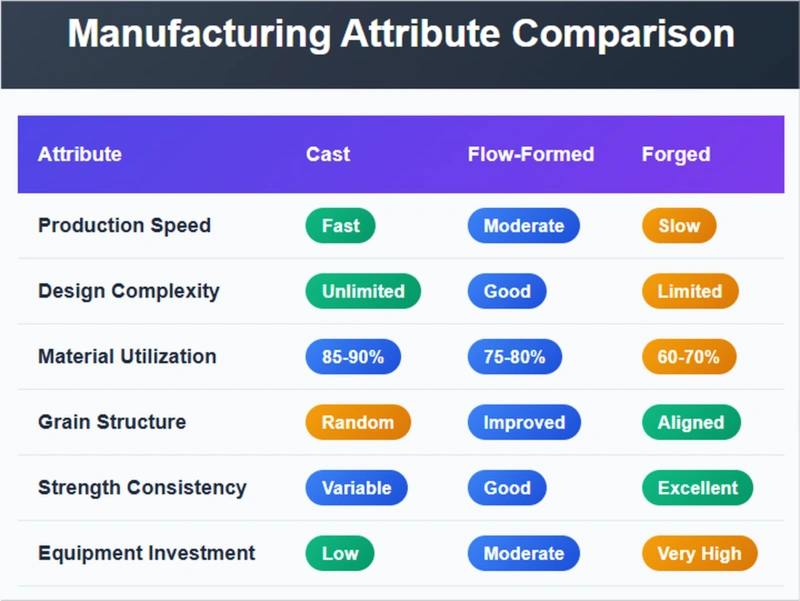

Direct Comparison: Cast vs Flow-Formed vs Forged

| Factor | Cast Wheels | Flow-Formed Wheels | Forged Wheels |

| Manufacturing Cost | Lowest | Moderate | Highest |

| Typical Weight | Heaviest | 10-15% lighter than cast | 20-30% lighter than cast |

| Impact Strength | Good for normal use | Very good | Excellent |

| Design Flexibility | Highest | Moderate | Limited |

| Repairability | Fair | Good | Excellent |

| Price Range | $150-400 | $250-600 | $500-1500+ |

| Best Applications | Daily drivers, winter wheels | Performance street cars | Track cars, extreme off-road |

Strength Differences in Practice

The strength differences between wheel types become obvious under extreme conditions. Cast wheels might crack from a severe pothole impact that would only dent a forged wheel. Flow-formed wheels fall somewhere between, offering better impact resistance than cast but not matching forged durability.

Weight Impact on Performance

Unsprung weight affects vehicle dynamics more than most people realize. Reducing wheel weight improves suspension response, decreases rolling resistance, and can even improve ride quality by allowing the suspension to better follow road irregularities.

The weight difference between a 20-pound cast wheel and a 15-pound forged equivalent might seem small, but multiplied by four wheels and factored for unsprung weight effects, the performance impact is noticeable in back-to-back testing.

Choosing the Right Construction for Your Needs

Daily Driver Considerations

For most daily drivers, quality cast wheels provide the best value proposition. They offer adequate strength for normal use, extensive design options, and reasonable pricing. The performance advantages of forged construction don't justify the cost premium for typical driving patterns.

Performance Application Requirements

Track days, autocross, and spirited driving increase the demands on wheel construction. The repeated stress cycles and higher impact forces encountered in performance driving favor stronger construction methods.

Off-Road and Heavy-Duty Use

Off-road driving subjects wheels to impacts and stresses that can quickly expose the limitations of cast construction. Rock strikes, pothole impacts, and side-loading from uneven terrain favor the superior strength of forged construction.

Aesthetic and Finish Considerations

Design Limitations by Construction Type

Cast wheels offer the most design flexibility, allowing for complex spoke patterns and intricate details. Different finishes and styles are readily available in cast construction, making them ideal for achieving sophisticated looks with integrated design elements that would be expensive to machine.

Forged wheels are typically limited to designs that can be machined from solid billets. This often results in a cleaner, more minimalist aesthetic that some prefer for performance applications.

Finish Durability

The manufacturing process affects how well different finishes hold up over time. Forged wheels' dense aluminum structure typically accepts and holds finishes better than cast alternatives. Paint, powder coating, and anodizing tend to be more durable on forged substrates.

Making the Informed Choice

Understanding your actual needs versus aspirational wants is crucial for making the right wheel choice. Most drivers overestimate their performance requirements and end up paying for capabilities they never use.

For guidance on selecting wheels that match your vehicle's requirements and your budget,Discounted Wheel Warehouse offers detailed specifications and expert assistance to help ensure you choose construction methods appropriate for your intended use.

Consider your driving patterns, performance expectations, and budget constraints realistically. The "best" wheel is the one that meets your actual needs without exceeding your budget or providing unused capabilities.

Frequently Asked Questions

Are forged wheels always better than cast wheels?

Not for every application. Forged wheels offer superior strength and weight characteristics but cost significantly more. For normal driving, quality cast wheels provide adequate performance at much lower cost.

How much lighter are forged wheels compared to cast?

Typically 20-30% lighter, depending on the specific designs being compared. The weight difference becomes more significant with larger wheel sizes.

Can cast wheels be used for track driving?

Quality cast wheels can handle occasional track use, but repeated high-stress conditions favor stronger construction methods. Flow-formed wheels often provide a good compromise for track day use.